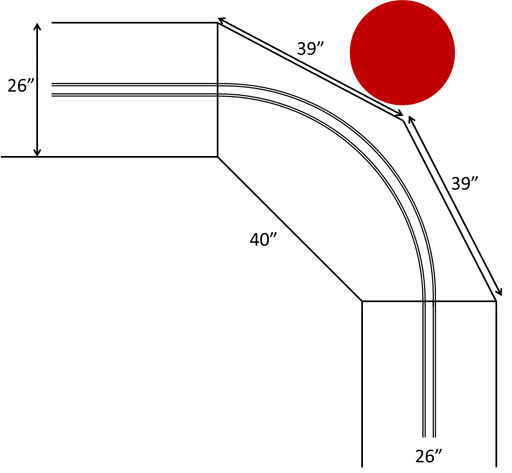

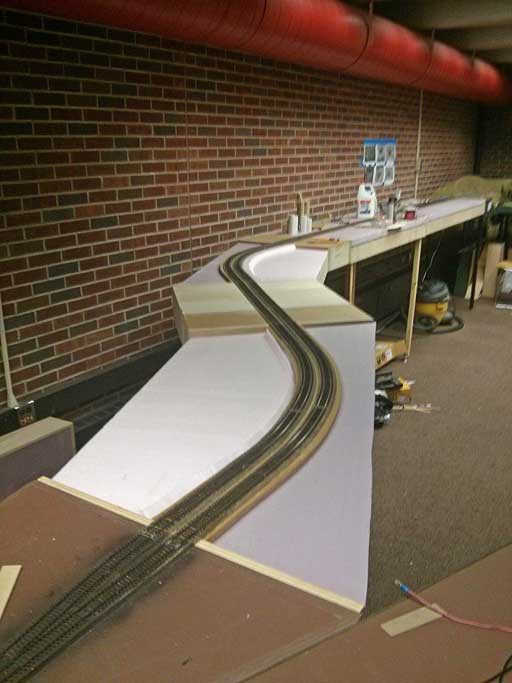

The year started with a discussion on how to incorporate the modules on hand into a layout that would efficiently use the room space. We have the Marias pass curve module set on loan from club member Jeff Crump but could not turn the corner with the other curved modules we have because of the width of the room. So time to build a curve module to fit the space!

This module is a double track 90° curve with a 42" radius outside track and 40" radius inside track. The module dimensions allowed us to avoid a large column and turn the corner so we could loop the layout around one end of the room.

The next need was for more industries on the layout. Stage at Joe's was no longer needed as a staging yard when David Kleme donated Wabash yard to the club. Time to re-purpose Joe's.

The two sections were stripped of the old code 100 track and new end plates and side frames and bracing added to shore up the old modules.

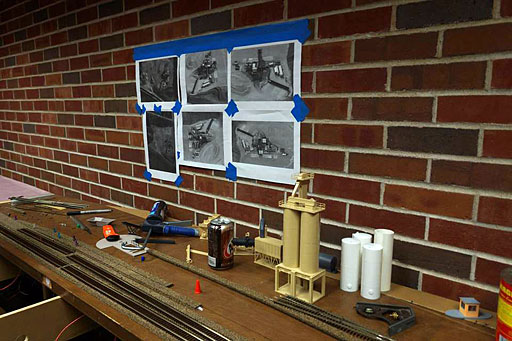

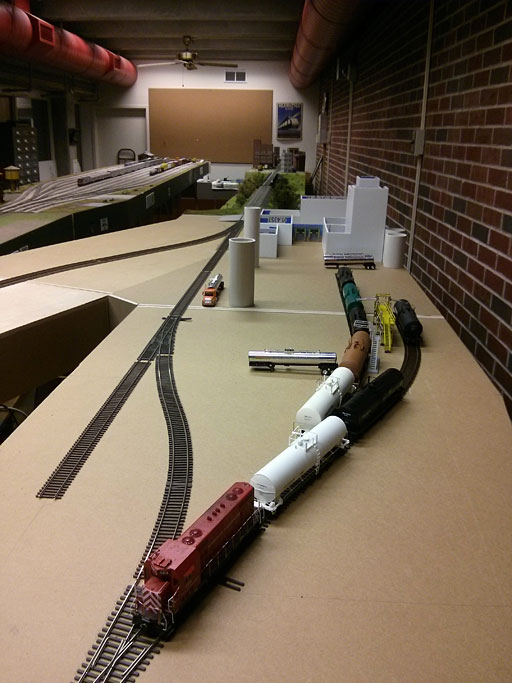

We came up with two new industry modules for the layout. As we had the Walthers Asphalt plant kit on hand we looked for a site in the Twin Cities with a plant near the rails. A site just south of Hastings fit the bill.

1-23-15

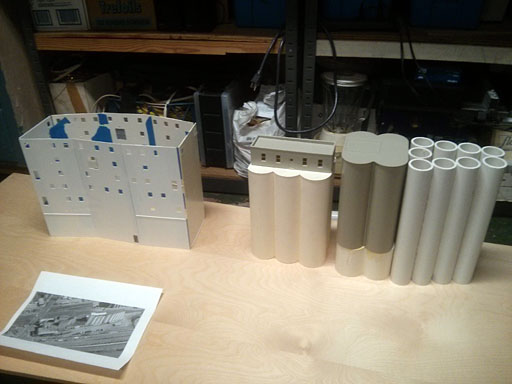

The Commercial Asphalt module begins to take shape

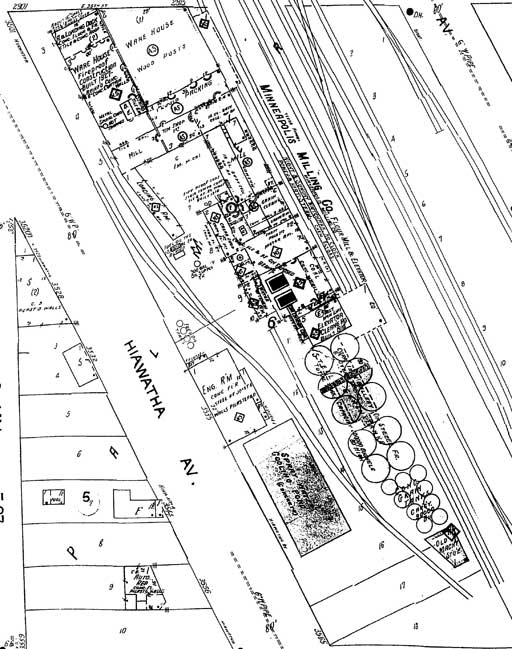

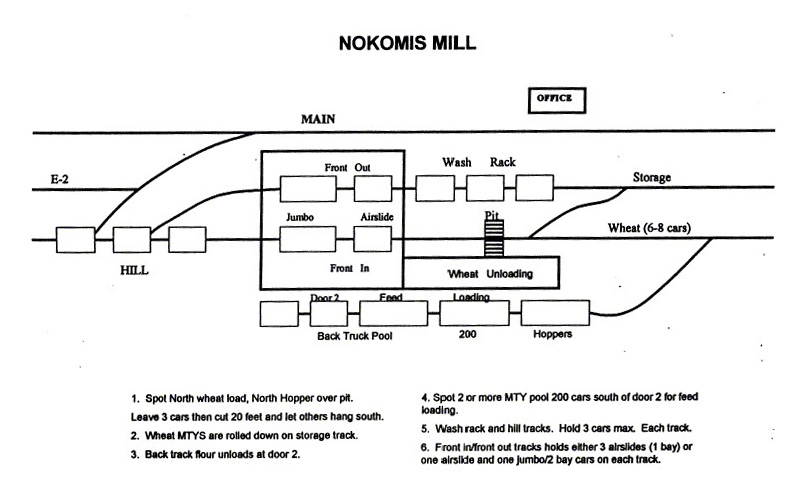

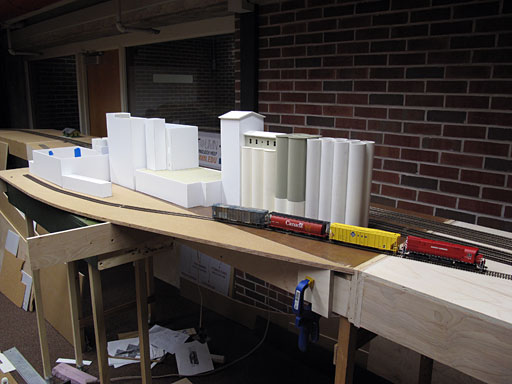

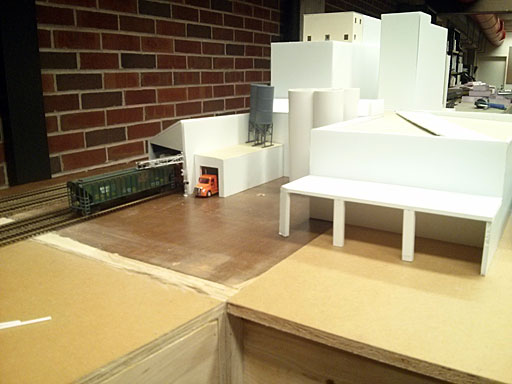

The second module set incorporating a Stage at Joe's section was the Nokomis mill complex at 35th and Hiawatha in Minneapolis

Minnesota Commercial Railway Nokomis Mill switching plans

1-23-15

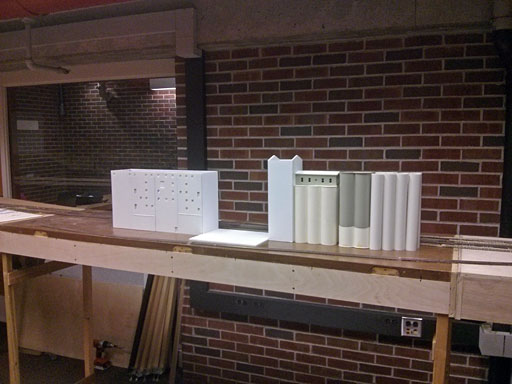

The mill module begins to take shape

Nokomis mill is a four section module

The two Joe's staging yard sections are now part of a large loop originating at Dakota junction. The loop also incorporates two curves and a straight double track module we build when the club was in 310 Williamson.

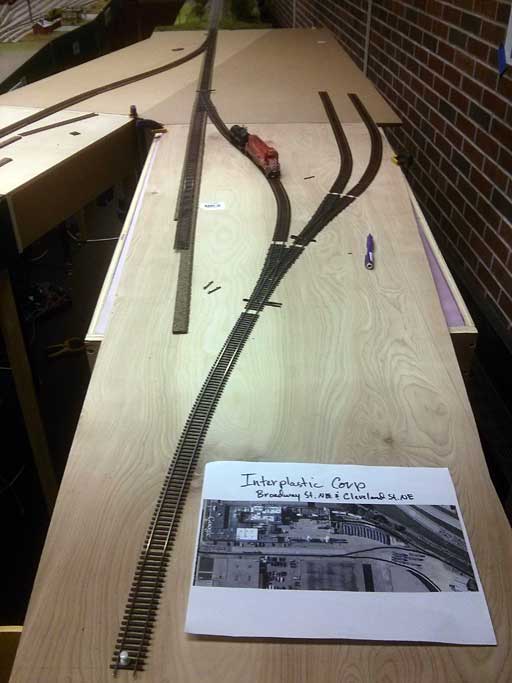

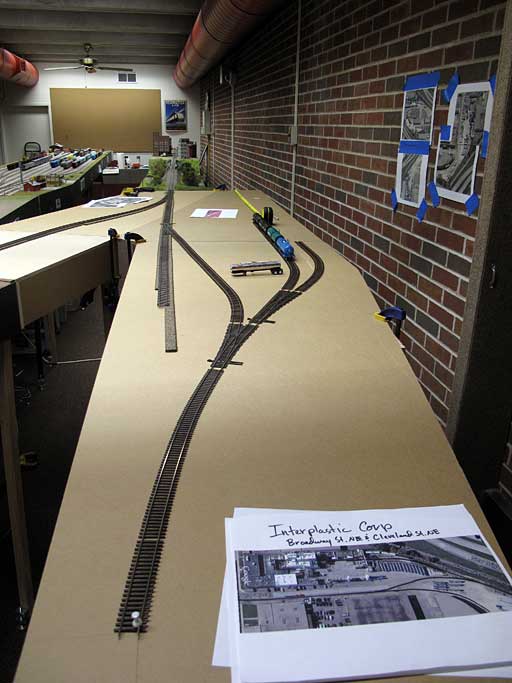

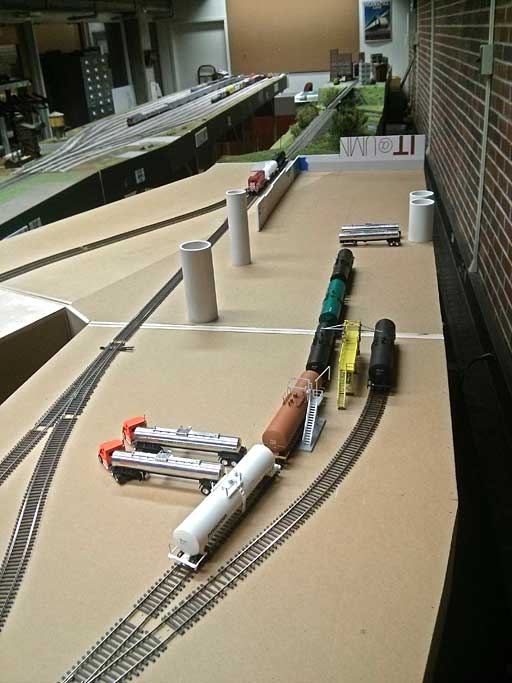

A third industry that was built to incorporate into the setup was the InterPlastics plant in Minneapolis. Both InterPlastics and Nokomis mill are switched by the Minnesota Commericial railroad.

2-10-15

Building the mill.

Kitbashing and adding scratch bit elements the mill starts to take shape!

2-12-15

2-27-15

3-5-15

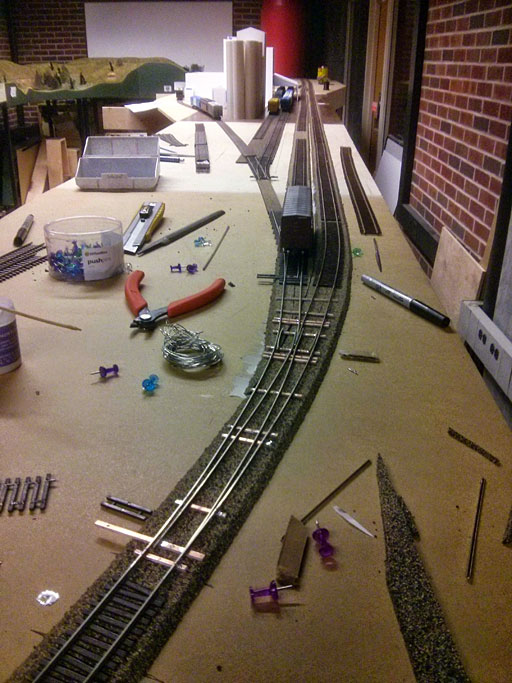

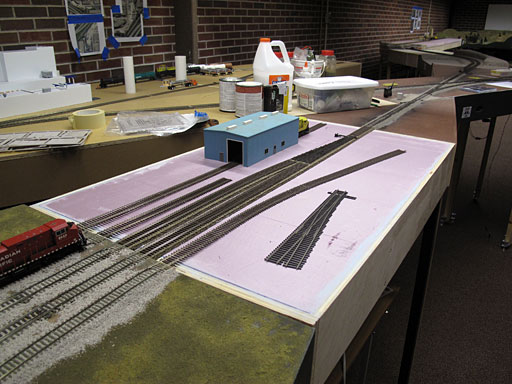

Track starting to get layed out

3-19-15

AJ Murphy built us a curved turnout for the Nokomis mill module!

3-21-15

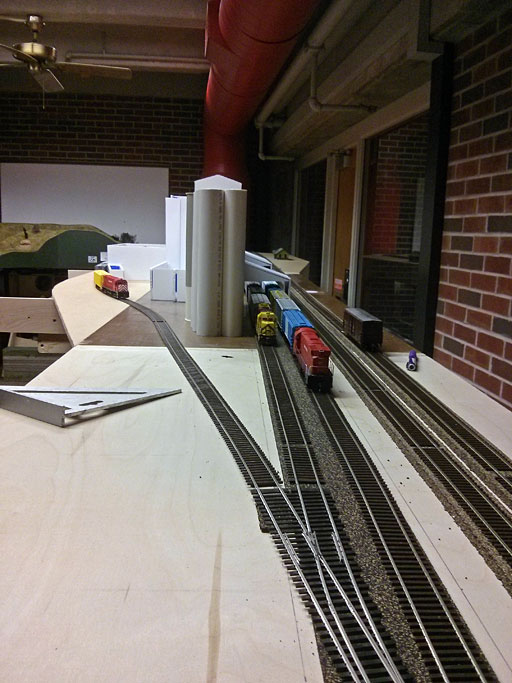

Backing a string of hoppers into Nokomis mill to test out the new turnout

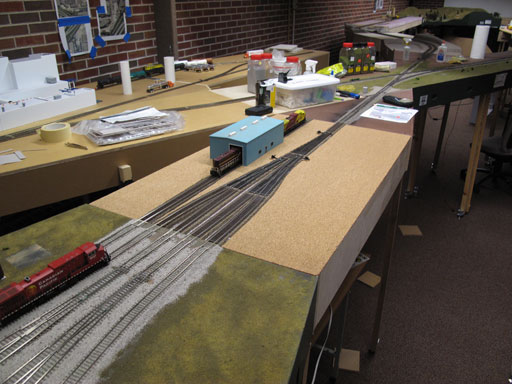

3-26-15

UMTC and MNNR power working the mill

Cork roadbed going down on Commercial Asphalt

East end of layout

4-2-15

Interpastics module sections cut out and trying on track for size

Nokomis mill - putting more of the pieces together

Unloading spot added to Hastings asphalt siding

Brian working on details for Dakota Junction

4-6-15 and 4-8-15

North end of Nokomis mill

4-21-15

Loading platform for InterPlastics

4-30-15

Pizza and trains

Adding some structure to InterPlastics

5-1-15

Building taking shape on InterPlastics

5-5-15

More progress on InterPlastics building

5-6-15

InterPlastics building gets a roof

5-14-15

InterPlastics loading docks and trailers

5-22-15

Roof details added to InterPlastics

6-5-15

MNNR switching InterPlastics

8-28-15

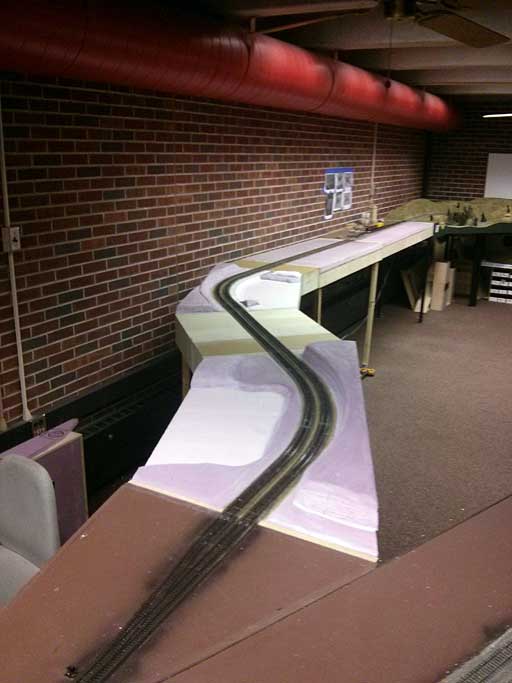

Foam added to 45° curve modules

10-29-15

Adding some foam to the 22.5° curves

Grass sprouting on Dakota Junction

11-05-15

Adding some relief to 45° curves

Nokomis mill north end. Bins and crossing posed to see how they look

11-7-15

Modules on the road! Wabash yard, 221 and the two 45° curves were included in a Minnesota Free-mo group setup at the Great Train Show in Shakopee MN

11-20-15

Modules back in Magrath

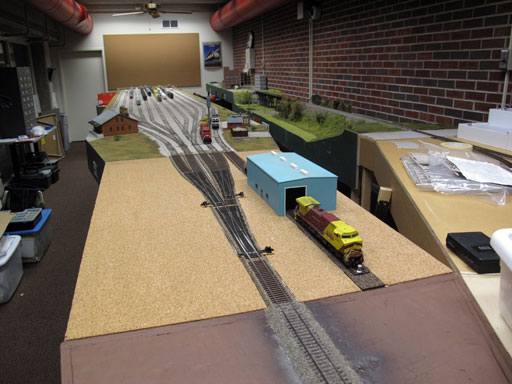

One of the modules (221) went out on loan to travel to Souix Falls SD for a Free-mo setup so we needed a new module for the Wabash yard throat. Here is one option - double track connection with three service tracks.

12-3-15

Wabash yard throat. Here is another option - four track connection with one loco service track.

Dakota Junction is getting greener!

12-16-15

Wabash yard throat progress. Added cork top to match the wabash yard profile - we went with the four track connection with one loco service track.

Field grass addition. Brian is trying out using fibers cut to approximate lenght and trimming with a small electric trimmer to get the effect he wants

12-18-15

Dakota junction wedge update. The track was not level between the main module and the wedge so track was removed; thin cork glued on to level out the roadbed and once dry and sanded down to give a level profile between the main module and the wedge a PCB tie plate will be layed across the joined sections and rail soldered into place.

Return to: B50 Magrath Layout Photos